48" 3 Uunts Sand Media Filtration System

- Payment: T/T, L/C

- Product Origin: Fuzhou, China

- Color: Black

- Shipping Port: Fuzhou

- Lead Time: 10 Days 100pcs

Strength

Strong

One-stop service, backbone enterprises

Guality

Good

Rich experience, excellent quality

Technology

Advanced

More than 40 sets of superior performance of a variety of advanced equipment

Service

Good

A unity and innovation, professional and trustworthy

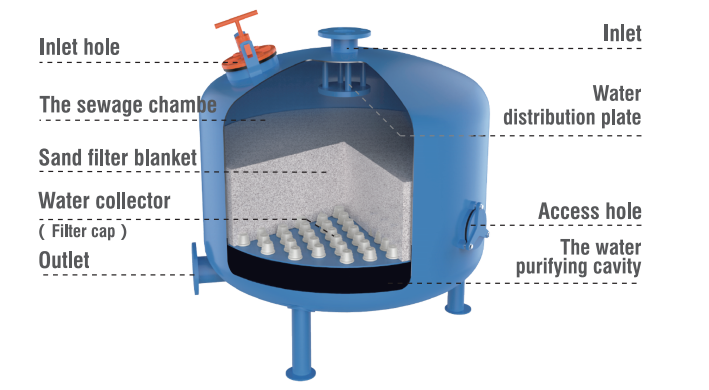

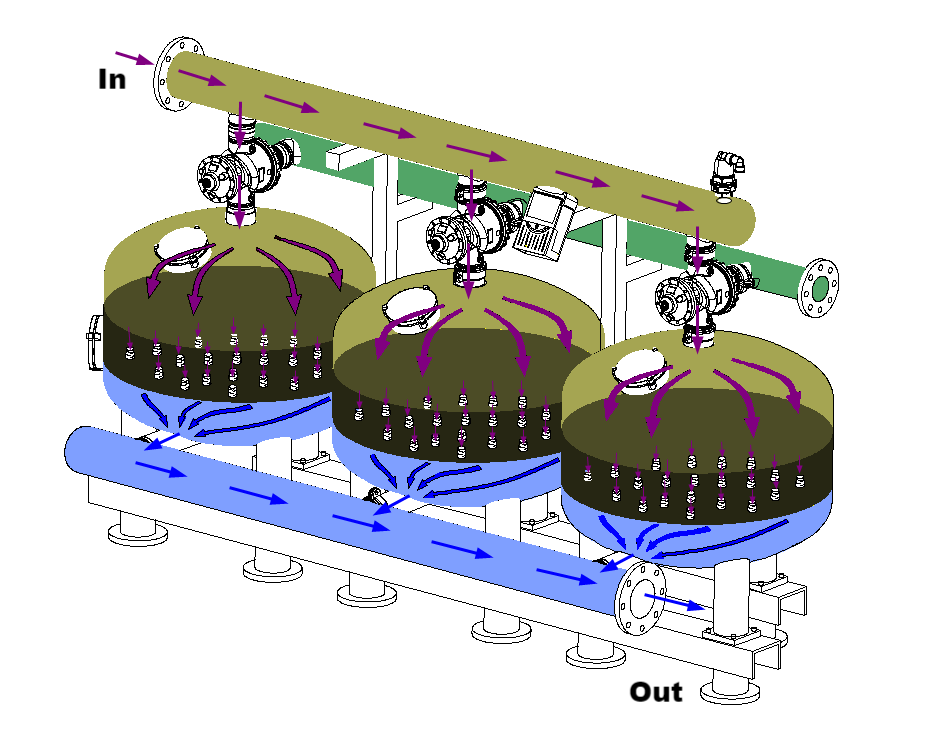

- ARCK's sand media filtration systems consist of one or more standard sand filter tanks. It can effectively remove suspended solids in sewage and reduce turbidity. It can be used in conjunction with the disc filter or mesh filter at the rear to achieve a perfect filtering effect.

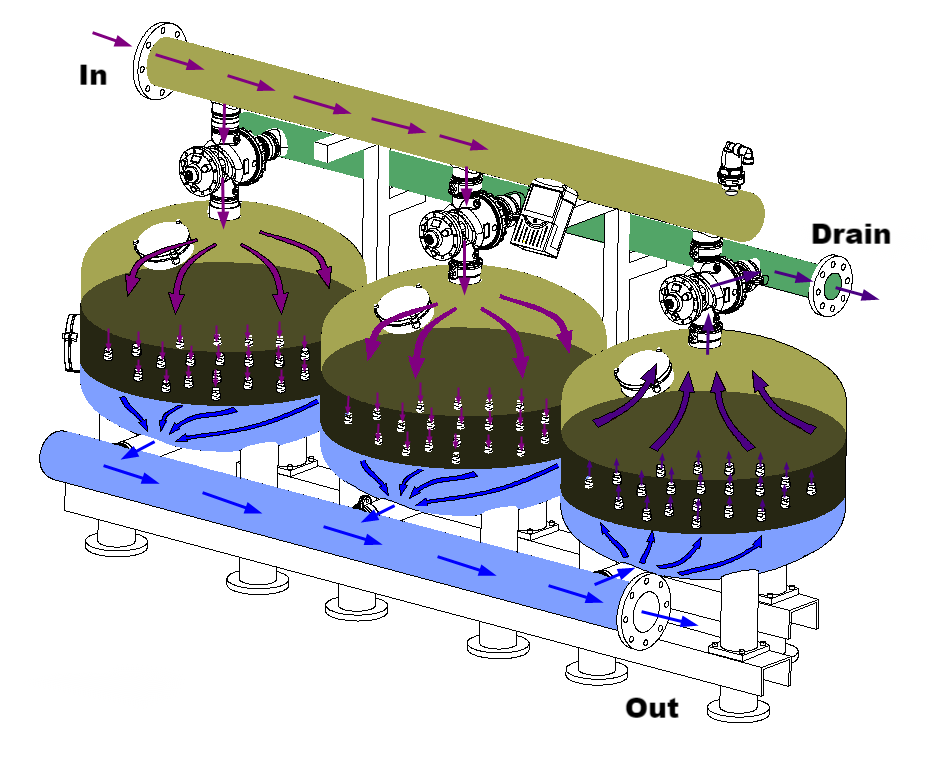

- It is a fully automatic water filtration system as it is equipped with hydraulic backwash valve and automatic controller. Under the command of the automatic controller, each sand tank can be backwashed one by one. Each sand tank is equipped with a water distributor and a water collector, which can realize the filtration requirements of large flow.

APPLICATION SCENARIOS:

• Irrigation field ---- farmland, garden, golf course, etc.

• Industrial field ---- water for industrial production, water for recycling and reuse

• Landscape field----fountains, water features, water curtains, etc.

• Surface water filtration field ---- river water, river water, lake water, sea water, etc.

ARCK's standard sand filter tank has an octagonal design for the water collector. Its unique precision gap can collect filtered water evenly. The water outlet is designed at the bottom, making the overall structure more compact and occupying less space. With anti-rust treatment, the sand filter tank becomes strong and durable.

ARCK's standard sand filter tank has an octagonal design for the water collector. Its unique precision gap can collect filtered water evenly. The water outlet is designed at the bottom, making the overall structure more compact and occupying less space. With anti-rust treatment, the sand filter tank becomes strong and durable.

- High filtration speed, low pressure loss, high filtration efficiency.

- Especially suitable for filtering suspended impurities in water.

- There are many sizes to choose from. From 16"(400mm) to 60"(1500mm)

- Stainless steel material, corrosion-resistant

- Configure automatic controller, built-in intelligent chip, can run automatically.

- Using quartz sand as filter medium.

- The maintenance port is reserved for easy cleaning and maintenance at any time.

The filter system consists of filter unit, three-way back flushing filter valve, automatic back flushing controller and other major components, and to connect with Y-type filter, air valve, pressure gauge, manifold, support frame and other spare parts , the filter unit is filled with the appropriate filter media.

| FILTRATION ACCURACY | BOTTOM SAND (cover water collector) |

UPPER SAND (12-38cm thickness) |

| Normal Filtering | 1.2-2.0mm | 1.2-2.0mm |

| Fine Filtering | 1.2-2.2mm | 0.5-0.8mm |

Backflushing

Filtering

Filtering:Under the control of the automatic controller, when the whole system are in the filter state, the sewage enter with the high pressure, through a unique water distributor to keep the water distribution filter sand smooth, the flow of laminar flow through the filler layer, Impurities are trapped in the filler layer. Through the bottom of the distribution of multiple water collectors, Filtered can clean water ,evenly collected through the outlet pipe out. The advection filter allows the filter to operate at high flow rates.

Backflushing:As the impurities accumulate in the filter medium, the pressure loss increases, and when the differential pressure increases to a certain setting value or reaches the setting cleaning time, the system automatically switches to the backflush state. The pressurized water enters the filter medium through the water collecting device, flushes it, separates the trapped contaminants and discharges the filtration system through the sewage outlet. The backflush ends after 2 minutes, the back flushing control valve returns to the filter state, then the rinsed filter tank continues to enter the filter working condition. The automatic controller issues an instruction to start the backflushing process of the next filter sand column ,until all the filter cylinders are rinsed again.

| Item No. | Sand Tank Number (pc) |

Sand Tank Diameter (mm/in) |

Control Valve (in) |

Inlet and Outlet Pipe Diameter (mm/in) |

Drain Pipe Diameter (in) |

Cackwash Flow (m3/h) |

Filtration Efficiency (m3) |

Amount of Quartz Sand (kg) |

Max. Working Pressure (mpa) |

Flow Range (m3/h) |

| ARCK16D2 | 2 | 400 16" | 2" | DN80 3" | 2" | 10 | 0.26 | 220 | 1 | 44915 |

| ARCK24D2 | 2 | 600 24" | 3" | DN80 3" | 3" | 20 | 0.58 | 500 | 1 | 30-50 |

| ARCK30D2 | 2 | 750 30" | 3" | DN100 4" | 3" | 35 | 0.91 | 640 | 1 | 30-70 |

| ARCK36D2 | 2 | 900 36" | 3" | DN100 4" | 3" | 45 | 1.31 | 920 | 0.8 | 60-100 |

| ARCK40D2 | 2 | 1000 40" | 4" | DN150 6" | 4" | 65 | 1.62 | 1120 | 0.7 | 90-130 |

| ARCK48D2 | 2 | 1200 48" | 4" | DN150 6" | 4" | 80 | 2.32 | 1600 | 0.6 | 100-180 |

| ARCK48D3 | 3 | 1200 48" | 4" | DN150 6" | 4" | 80 | 3.48 | 2400 | 0.6 | 150-270 |

| ARCK48D4 | 4 | 1200 48" | 4" | DN200 8" | 4" | 80 | 4.65 | 3200 | 0.6 | 200-360 |

| ARCK48D5 | 5 | 1200 48" | 4" | DN200 8" | 4" | 80 | 5.81 | 4000 | 0.6 | 250-450 |

| ARCK48D6 | 6 | 1200 48" | 4" | DN200 8" | 4" | 80 | 6.97 | 4800 | 0.6 | 300-540 |

| ARCK60D2 | 2 | 1500 60" | 4" | DN150 6" | 4" | 130 | 3.64 | 2500 | 0.6 | 160-220 |

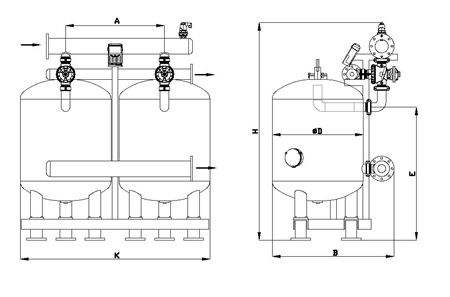

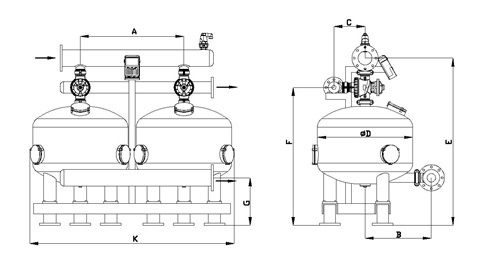

| Item No. | D (mm) |

A (mm) |

B (mm) |

C (mm) |

E (mm) |

F (mm) |

G (mm) |

K (mm) |

H (mm) |

| ARCK16D2 | 400 | 500 | 640 | — | 1030 | — | — | 1100 | 1670 |

| ARCK24D2 | 600 | 700 | 840 | — | 1080 | — | — | 1540 | 1770 |

| ARCK30D2 | 750 | 850 | 550 | 290 | 1530 | 1320 | 360 | 1780 | — |

| ARCK36D2 | 900 | 1100 | 627 | 290 | 1580 | 1380 | 370 | 2150 | — |

| ARCK40D2 | 1000 | 1200 | 703 | 290 | 1650 | 1420 | 370 | 2320 | — |

| ARCK48D2 | 1200 | 1320 | 803 | 290 | 1750 | 1590 | 400 | 2650 | — |

| ARCK60D2 | 1500 | 1620 | 960 | 290 | 1870 | 1600 | 470 | 3120 | — |

|

ARCK16D2andARCK24D2 |

ARCK30D2;ARCK36D2;ARCK40D2;ARCK48D2;ARCK60D2 |

||||||||

Strength list

Our honor

Enterprises and workshops

Tel: 0086-591-83423525

Mobile phone: 0086-18650792231

E-mail: ARCK@dripsirrigation.com

Address: No. 251 Xixi, Xinju Village, Yangxia Street, 350323,Fuqing, Fuzhou, Fujian